MODERNIZATION AND OPTIMIZATION OF SYSTEMS & PLATFORMS

Midstream companies are often using multiple technology ecosystems that are antiquated, functionally insufficient and contain an overwhelming amount of isolated data (spread across numerous systems), often as a result of ongoing M&A activity. These old and lagging systems can expose midstream companies to cybersecurity risks and inhibit a company’s ability to operationalize their growth strategies.

With many midstream companies having avoided IT expenditures for significant periods of time, the need to modernize has become critical. While platform modernization has become a key enabler in this space, midstream companies are struggling to successfully deploy and transition to new order-to-cash and other digital technologies, as evidenced by numerous failed projects.

Whether you are upgrading a legacy system, wanting to develop a custom application or audit an existing implementation, finding the right technology partner that understands the midstream space, the vendor landscape, and has the project management and technical skills necessary to help their clients successfully deliver a digital transformation project is essential and down-right critical.

IMPROVING EFFICIENCY AND MAXIMIZING RETURN ON ASSETS

As midstream companies look to scale for growth, digital transformations are required to meet the operational efficiency and safety mandates in the field, as well as the risk management and profitability demands of the board room. Digitization of manual/paper-based processes is long overdue, and processes need optimization and automation.

Midstream companies need more sophisticated tools for maximizing their return on existing assets, such as tools that help reduce downtime and unplanned outages. Digital solutions that combine commercial and operational data in new, innovative ways provide a competitive advantage today and will ensure a company’s relevance into the future.

MATURING DATA INTEGRATION AND DATA ANALYSIS

For many midstream companies, the patchwork of legacy systems has created a siloed effect on the organization’s people, processes, data and technology. Additionally, decreased costs and increased usage of sensors and new sensor technologies are generating more data than ever before. Massive amounts of data are available, but organizations need to mature their ability to extract value from this data. For efficiency and data integrity reasons, all systems need to communicate with each other.

Capco utilizes best practices to develop and implement optimal solutions that integrate data between systems seamlessly. Pricing data, logistics systems, ERP (sub-ledger <-> general ledger), data warehouses, and credit systems are just a few of the common examples of systems integration projects. Without improving, midstream companies will miss the commercial and operational opportunities buried in the data fragmented across disparate systems as well as the potential threats that can be identified.

Advanced analytics and techniques are required to transform the midstream organization from a data generator into an IoT enabled, data-powered entity.

REDUCING OPERATIONAL AND REPUTATION RISK

Outdated operational control systems are unable to provide enough data for insights, operations and audit, exposing midstream companies to the risk of preventable unplanned outages, or worse, avoidable leaks or spills. Leaks damage both the company and the midstream industry, impacting public opinion and discussions on critical topics, such as right-of-way easements, government policy and new growth opportunities.

The ability to combine real-time operational data with physical asset data with geospatial data and perform advanced analytics with end-user visualization capabilities will define a new standard in pipeline integrity for the industry.

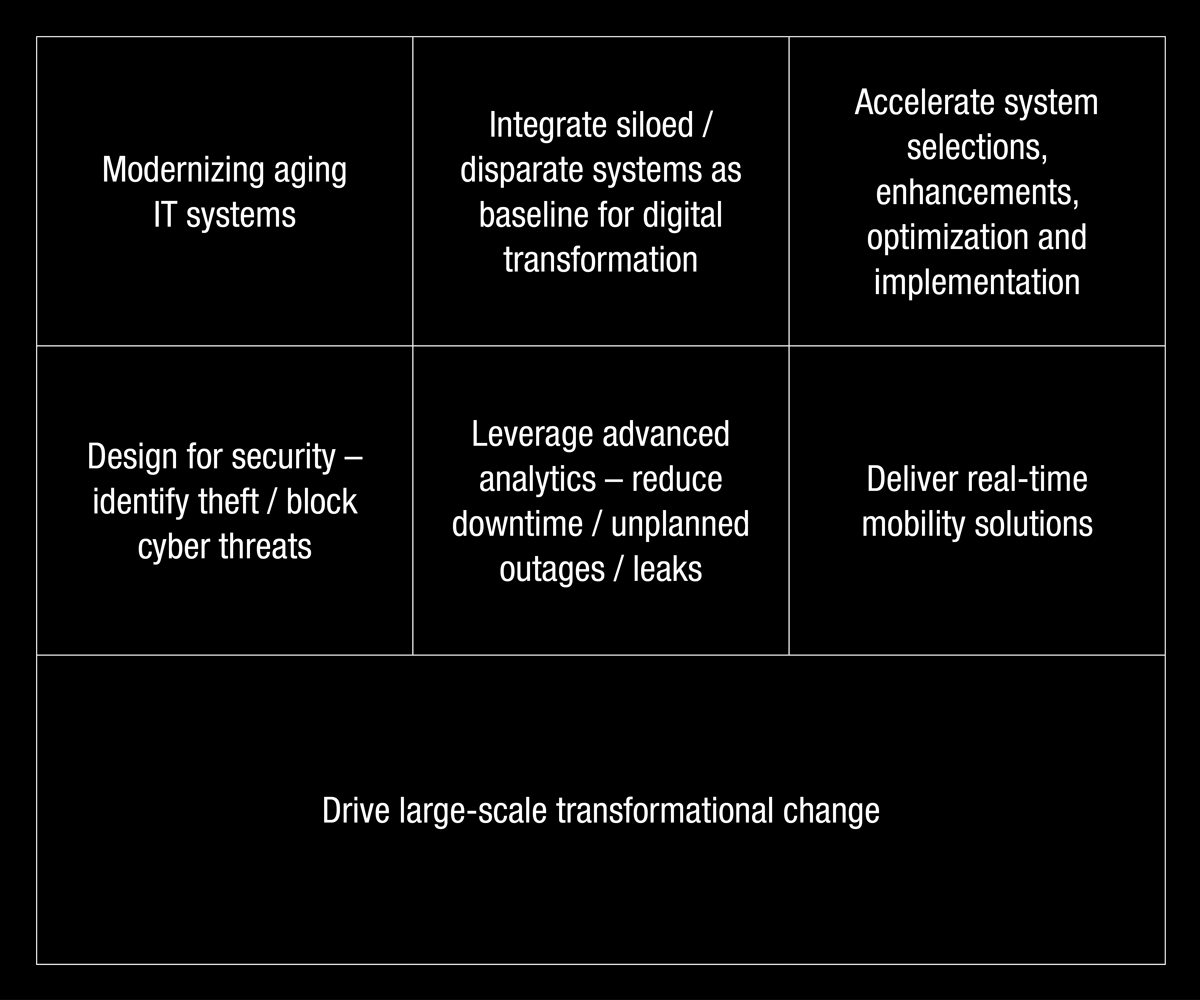

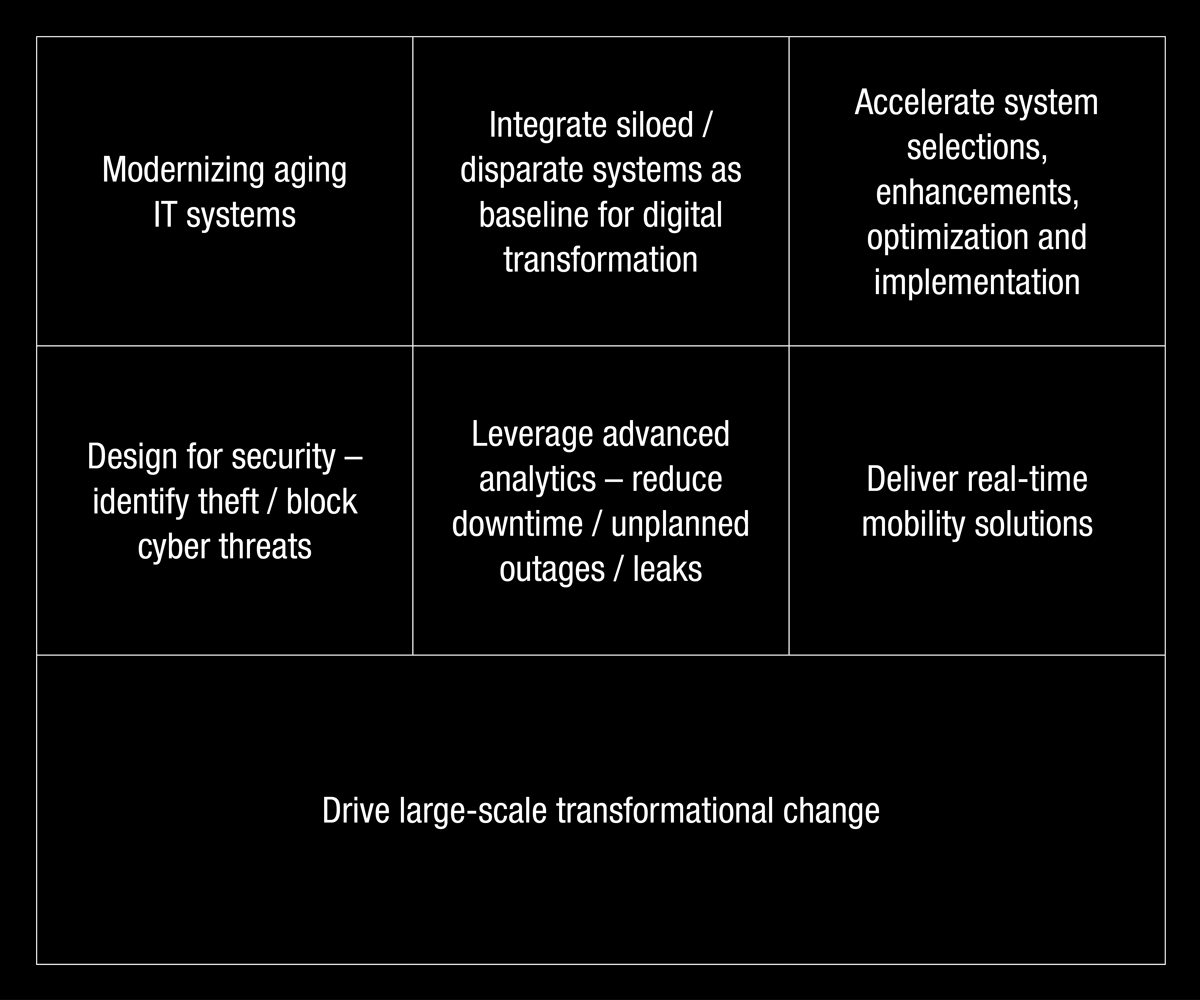

We partner with midstream companies to transform their business, capitalize on new opportunities in the following ways: